Septic Systems

Septic tanks are installed on, with a few exceptions, all septic systems. A septic tank is a dual-chamber, single tank made of either concrete or plastic that accepts raw sewage from the source (your house). Water enters the tank in what is called a baffle, which guides incoming sewage deeper into the tank. This allows the separation of solid material to begin. Heavier types of solids, along with older solids that have been inside the tank a while, sink to the bottom. This layer of solid material is called sludge. The lighter and newer solids float to the top of the tank, which is referred to as scum.

Between the layers of scum and sludge is wastewater that does not hold any solids. This is commonly known as the clear layer. Inside the tank is a hole that separates the two chambers. This partition has about a 4” round hole halfway down. This hole allows the clear water to flow into the next chamber. This chamber stores water that will be dispersed into the drainfield, (sometimes known as the leach field). On the outlet side of the septic tank is another baffle, which serves two purposes: first, the filter inside the baffle prevents any solids that have made it into the second chamber from going out into the drainfield. Second, the baffle serves as a way to draw water from the middle layer and disperse it into the drainfield. This side of the septic tank is supposed to be free of solids, but the baffle acts as insurance.

Over time, sludge layers and scum layers settle, building up into thicker deposits. These deposits are why it is a good idea to pump your septic tank at least once every three years. If these deposits get too thick, they can make their way into the liquid chamber and eventually out into the drainfield, or plug up the filter if one is installed. Solids will plug up the drainfield and prevent it from dispersing water into the ground, causing flooding at the tank and making a mess of the site.

Click Here to Download the Simply Septic Brochure supplied by DNREC

Contact Us Today

Dose Tanks

Dose tanks are installed on all pressurized drain fields but can also serve other purposes. Generally, these tanks are also made of concrete or plastic. Wastewater flows from the outlet side of the septic tank into the dose tank. The dose tank serves as a sewage pump and control tank. The sewage pump and its controls are placed inside of the tank. As wastewater flows into the tank, the water level rises. Floats are installed to turn the pump on and off at certain water levels. When the water level reaches the designated level, the float turns the pump on, which discharges the water out into the drainfield.

As the pump runs, the water level lowers until it reaches the designated level in which the float turns the pump back off. There is a high-level alarm float that serves as a warning to the homeowner when the water level is getting too high and something has probably gone wrong.

The high level alarm is attached to a box that sounds a siren and light, either at the surface or in the house. The dose tank has a vent pipe at the surface that allows air to vent into and out of the system as the water level rises and falls. Dose tanks also have an electrical control box for managing the floats and pump so they work on a timer. All pressure systems work on timed doses to prevent overdosing the drainfield at peak times.

Gravity Septic System Drainfields

Dose tanks are installed on all pressurized drain fields but can also serve other purposes. Generally, these tanks are also made of concrete or plastic. Wastewater flows from the outlet side of the septic tank into the dose tank. The dose tank serves as a sewage pump and control tank. The sewage pump and its controls are placed inside of the tank. As wastewater flows into the tank, the water level rises. Floats are installed to turn the pump on and off at certain water levels. When the water level reaches the designated level, the float turns the pump on, which discharges the water out into the drainfield.

As the pump runs, the water level lowers until it reaches the designated level in which the float turns the pump back off. There is a high-level alarm float that serves as a warning to the homeowner when the water level is getting too high and something has probably gone wrong.

The high level alarm is attached to a box that sounds a siren and light, either at the surface or in the house. The dose tank has a vent pipe at the surface that allows air to vent into and out of the system as the water level rises and falls. Dose tanks also have an electrical control box for managing the floats and pump so they work on a timer. All pressure systems work on timed doses to prevent overdosing the drainfield at peak times.

LLP Septic System Drainfields

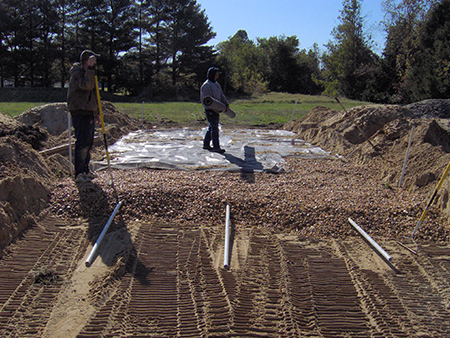

Low-Pressure Pipe drainfields are 12’ wide trenches with aggregate and pipe. The pipe is pressurized with a pump located in the dose tank and has small holes on the bottom that allows water to enter the aggregate. The water filters through the aggregate and into the surface of the soil, where at that point, the water begins to soak into the soil. The fact that the pipe is pressurized means water will come out of all the holes in the pipes at the same time. This causes the entire drainfield area to receive an equal amount of wastewater at once. The pipe leaves the dose tank and leads into a manifold. The manifold has lateral pipes attached to it, and when the pump comes on, it pumps water to the manifold and out of the laterals. LPP technology is extremely effective, but these types of systems generally do not have as long of a lifespan as a gravity septic system or mound septic system.

Mound Septic System Drainfields

Mounds are the dreaded “hill in the yard” and are pressurized by a pump just like an LPP. The pipe leaves the dose tank and leads to a manifold, at which all of the lateral pipes are attached. The laterals with the holes are placed inside an aggregate bed. This pump allows the entire drainfield to receive water to all the holes at the same time. This is called equal distribution. Mounds are constructed by placing a layer of sandy fill under an aggregate bed with laterals inside. Then the aggregate (stone) bed is covered with sandy fill.

It is very important to maintain a mound septic system’s grass. It is not a good idea to allow a lot of foot traffic or activities to happen on the mound system. Anything that allows the soil to be removed from the sides and/or top of the mound will cause premature “blowouts”. Blowouts are areas where sewage begins to surface. Since the mound is above the ground, it erodes soil a lot easier if proper maintenance isn’t performed. Walking up and down the mound can cause the soil to erode also. All of these reasons make it very important to have a good, mowed grass surface on the mound area.

Nitrogen Reduction Units

Nitrogen reduction units are a way of reducing the nitrogen content in wastewater along with other pollutants. Nitrogen is one of the major sources of pollution infecting our waterways. DNREC has approved regulations that are the beginning of requiring nitrogen reduction on septic systems located anywhere near a water source that is in close proximity to our Inland Bays or the Chesapeake Bay. The units have filters that sit inside the liquid chamber of septic tanks. The basic process involves wastewater being introduced at the top of these filters which settles down to the bottom. Some of the wastewater from the bottom goes out toward the drainfield/dose tank, and some of the wastewater goes back to the top of the filter. Oxygen is pumped into the filter to help the tank accomplish the denitrification process. The oxygen comes from a pump at the surface. We typically place the pump inside of a waterproof container and locate it directly above the septic tank.

Peat Systems

Peat systems are a way of reducing bacteria in wastewater along with other contaminants. A peat system is a plastic container that contains peat moss. Wastewater is pumped into the top of the container. Wastewater then soaks down through the peat moss to the bottom of the container. The bottom of the container has holes that allow water out of the container. The container usually sits on a aggregate bed. As water leaves the peat unit, it enters the aggregate bed. We also use peat systems in place of sand mounds as peat systems take up much less room than a sand mound.

Peat Systems

RECENT POSTS

How Well Drilling Works

If you live in an area where public water isn’t readily available, well water is your best bet. But how exactly does well drilling work? Willey & Co are Delaware’s trusted well drilling experts, and we’ll take you through the process of drilling a well and what you need to know before getting one for…

Read MoreWhat to Expect With Your Water Well Maintenance

If you rely on a well for your home’s water supply, it’s essential to keep it maintained to ensure it continues to function efficiently. The last thing you need for your Laurel, DE home or business is to be suddenly without water, especially when you need it the most. Regular water well maintenance from Willey…

Read MoreHow Does a Well Pump Work?

A well pump is a vital piece of equipment typically used to extract water from the ground in homes, farms, and other establishments that rely on well water. If your Laurel, DE home or business uses a well to obtain fresh water, it’s essential to understand how a well pump works to maintain and troubleshoot…

Read MoreSeptic Installation Services in Delaware

Willey & Co. is Delaware’s premier septic installation services provider. With over 40 years of experience, they are highly skilled in the installation of septic systems. Using the latest technology and highest quality materials, Willey & Co. is able to ensure your septic system is installed quickly and correctly the first time. Not only do…

Read More